Blog

Titanium and Ceramic Luxury Watches: What Collectors Need to Know

From Rolex and Audemars Piguet to Richard Mille and Patek Philippe watches, raw materials can make all the difference for the discerning collector. Traditionally, luxury wristwatches were composed of gold, silver, and other precious metals.

In the 1930s, watchmakers began to use stainless steel in their products. Its ability to withstand nicks, dents, scratches, rust, and corrosion has made stainless steel a common choice for anyone who values durability over glamor.

While no other practical watch material is definitively stronger than stainless steel, both titanium and ceramic alloys have proven to be incredibly rugged. Furthermore, each offers its own distinctive advantages over stainless steel in many quality categories that are extremely important to collectors who truly appreciate a fine wristwatch.

Why Titanium and Ceramic Matter in Modern Watchmaking

Titanium and ceramic watches can take a beating and still look great. Beyond durability, each of these materials comes with its own set of amazingly beneficial characteristics.

Although some grades of stainless steel are harder and more heat-resistant than titanium, titanium has a significantly higher strength-to-weight ratio. Because it is so much lighter than steel, it is an ideal material for a highly comfortable wristwatch.

While stainless steel can generally withstand violent impacts better than ceramic alloys, ceramic is lighter and can be up to four times harder. This makes a ceramic wristwatch easy to wear and extremely wear-resistant.

Beyond their light weight and general durability, titanium and ceramic are hypoallergenic and impervious to corrosion. Both materials are also aesthetically striking, lending watches a sleek and modern look.

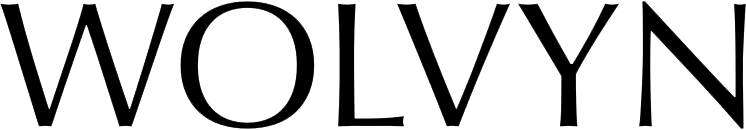

Rolex and the Evolution of Ceramic Craftsmanship

A longtime leader in precision timekeeping, the iconic Swiss watchmaker Rolex has a stellar reputation for making watches that are incredibly rugged and strong. In the early 2000s, it took its commitment to durability to a whole new level by establishing its own proprietary, in-house ceramic alloy under the brand name Cerachrom.

Much harder than steel, Cerachrom lends watches a look that is both organically raw and delicately elegant at the same time. Rolex began by using Cerachrom as a substitute for aluminum in their bezel inserts, but over the years, it expanded its use of its signature ceramic alloy to make dials and cases as well.

Titanium’s Rise in High-End Horology

Admiring titanium’s incredible physical properties, the timepiece companies began using this aerospace material for internal components in the 1960s. But the first wristwatch manufacturer to take full advantage of the strength, lightness, and corrosion-resistance of titanium was Citizen Watch.

Composed of 99.6% pure titanium, its Citizen’s X-8 Chronometer kicked off nothing short of a revolution in watchmaking. Decades before Cerachrom, titanium gave consumers a wristwatch that didn’t have to be heavy to be light. Beyond its use in moving parts, titanium is a great choice for cases, crowns, bezels, and bracelets.

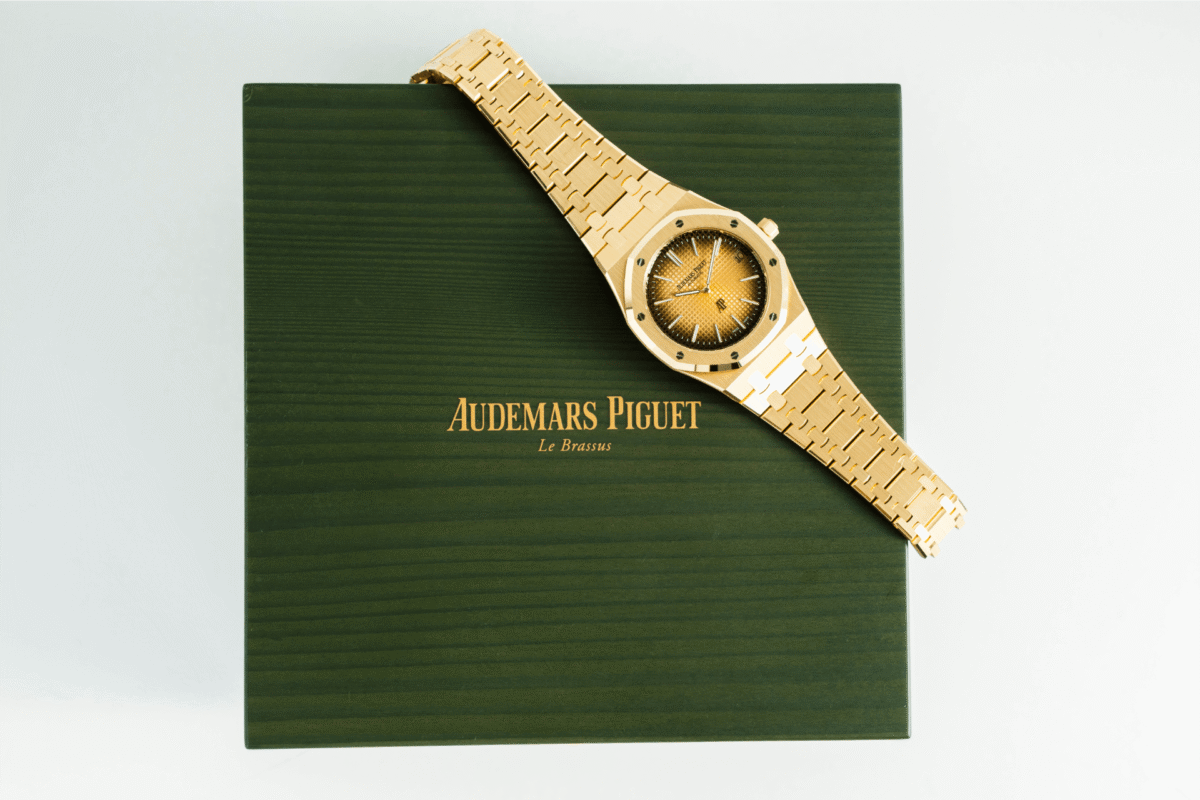

The Material Behind the Prestige: Finishing and Feel

The look and feel of high-quality materials like titanium and carbon are a big part of their overall appeal for wristwatch collectors. Common finishes for these materials might vary from bead-blasted to high polish.

A great option for a ceramic watch, a bead-blasted finish leaves a matte, non-reflective surface with a soft, muted texture that resembles brushed satin. This finish is created by bombarding watch parts with small spherical particles of ceramic or glass under high pressure.

At the other end of the finish spectrum, a high polish finish stresses sparkle and shine. When thoroughly polished through sanding and buffing, titanium produces a highly reflective, mirror-like surface that catches any ambient light.

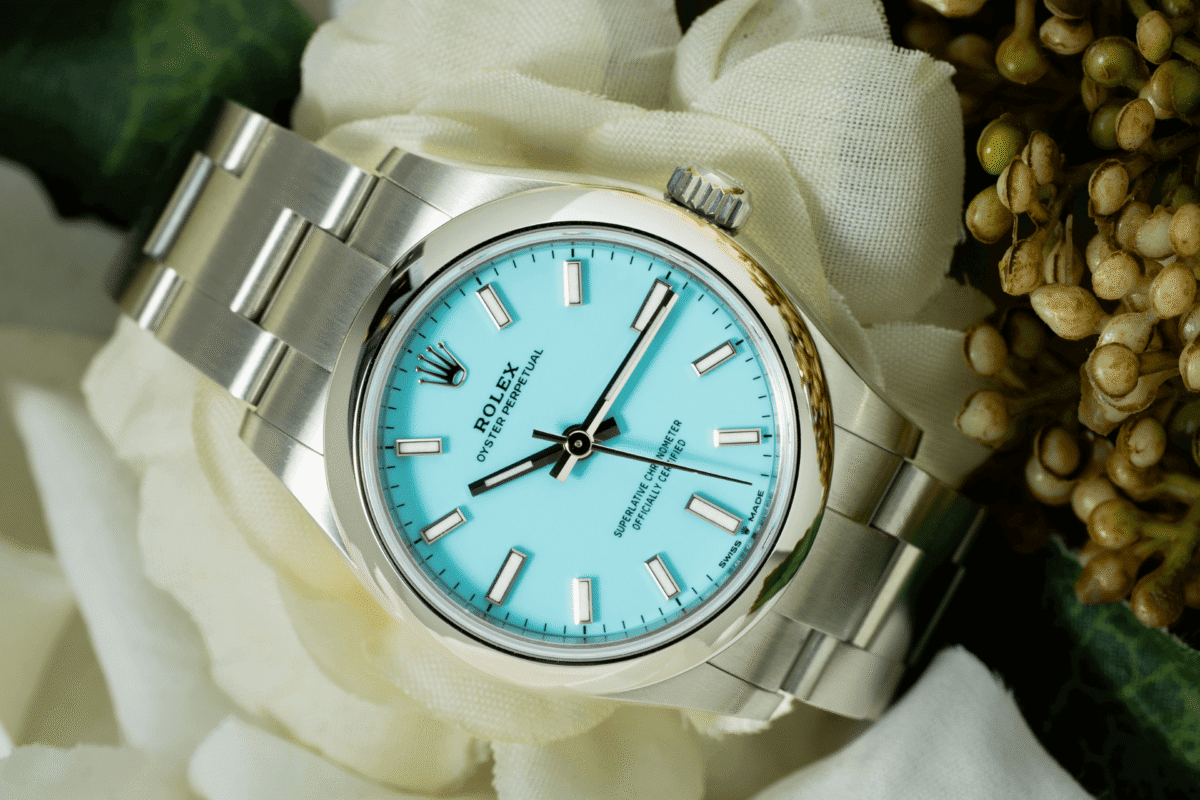

Icons Leading the Material Revolution

For a long time, high-end watch manufacturers used only precious and proven metals like gold and stainless steel. With their prestigious associations and promises of longevity, these materials have shaped the history of watchmaking.

But, faced with the imperatives of a faster, more technological, and more ecologically responsible world, watchmaking artisans have naturally been led to rethink and expand their range of materials. Today, Rolex, Audemars Piguet, Richard Mille, Patek Philippe, and other icons of modern watchmaking are leading a material revolution that goes far beyond titanium and ceramics to include carbon fiber, synthetic sapphire, and proprietary gold alloys.

Collectors’ Takeaway

Lightweight, aesthetically pleasing, hypoallergenic, and resistant to corrosion, oxidization, dents, and scratches, titanium and ceramic alloys make outstanding materials for wristwatches. Leading manufacturers, such Rolex, Audemars Piguet, Richard Mille, and Patek Philippe, have made the most of these value-add materials, creating a whole new generation of watches that have transformed the watchmaking industry. Let the watch specialists at WOLVYN help you find the perfect titanium or ceramic watch for you!